-

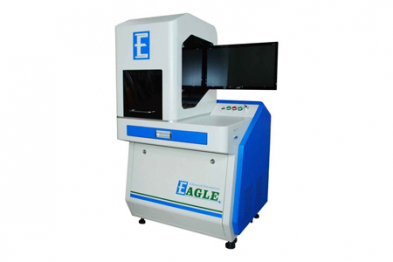

Eagle X-7050 Desktop Laser Engraving Machine

GM-EAG-X7050Working Area: 27.5″ x 19.7″ (700 x 500mm)

Max. Workpiece Height: 6.7″ (170mm) by motorized Z axis, can accommodate abnormally shaped work pieces.

Working Table*: A stainless steel plate table for engraving, and a full-support honeycomb table for cutting.

Laser Source: CO2 RF Metal Laser Tube

Laser Power: 40W

Laser Configuration: Single laser

Focus Lens: Standard 2″ (50.8mm)

Software: EagleWorks CAD/CAM and EaglePrint print driver, compatible with Windows 7/8/10. 100% support LightBurn software.

Machine/PC Connection: USB / FLASH / LAN / WLAN

Operating Mode: Engraving / Cutting / Combined

Control Interface: True Color TFT LCD panel with function buttons.

Memory Capacity: Multiple jobs storage up to 128M.

Resolution: Up to 4064 DPI.

Motion System: Transmission with belt on advanced linear rails, driven by stepper motors.

Accessories: Air assist pump and exhaust blower integrated inside the machine cabinet.

Electrical Requirement: 220V/50Hz, single phase, up to 1.0kW.

Size: 43.3″ x 37.4″ x 18.5″ (1100 x 950 x 470mm)

Net Weight: 260lb (120Kg)Issue rendering sage

The X-7050 desktop laser engraving machine, with 27.5″ x 19.5″ (700 x 500mm) working area, offers a portable desktop solution for high quality engraving and cutting of acrylics, cardboard, wood, textiles, two-color sign laminate, stones and much more. Eagle laser machines are the most robust, accurate, and reliable on the market.

• Portable size

• Motorized Working Table and Front-Door Table Access

• Automatic Focusing -

Eagle X-1309 CO2 Laser Cutting Machine

GM-EAG-X1309Which laser configuration is best for me?

You should choose single laser configuration if your primary needs is processing work pieces larger than half of the working table.Dual laser systems include two laser heads, allowing you to cut or engrave twice as much material in the same amount of time. Each laser has an independent set of laser source, optics and power supply which you can enable or disable according to processing needs. The spacing between the heads can be adjusted at any time using just a screwdriver.

130W CO2 laser is the most cost effective choice for cutting (can cut acrylic up to 1" in thickness). 150W CO2 laser is best suitable for cutting ultra-thick materials (can cut acrylic up to 1-1/4" in thickness). While 100W CO2 laser is better choice for precise engraving and cutting a little thin material (can cut acrylic up to 3/4" in thickness).

What about motor options?

With servo motors from world’s leading supplier, the laser head of the X-1309 can move very fast at extremely high resolution. A step size of just 6.25μm gives the machine a resolution of over 4000DPI. In arbitrary-direction cutting, the head can accelerate at 2 m/s2 (0.2G), while for X-axis scanning during engraving, acceleration up to 20 m/s2 (2G) is possible. The X-1309 with high quality stepper motors sacrifices only a small amount of performance.Working Area: 51″ x 35″ (1300 x 900mm) Can fit uncut sheets or long work pieces (along Y direction) with full pass-through capability.

Max. Workpiece Height: 8″ (200mm) by motorized Z axis, can accommodate abnormally shaped work pieces or an optional rotary unit for use with pipe and rod stock.

Working Table*: An aluminum strip table for hard and flammable materials (acrylic, cardboard, wood, etc.), and a full-support honeycomb table suitable for soft material processing (paper and textiles).

Laser Source: CO2 Sealed Glass Laser Tube

Laser Power*: 100W / 130W / 150W

Laser Configuration*: Single / Dual laser(s)

Focus Lens*: Standard 2.5″ (63.5mm), optional 4″ (101.6mm), or 2″ (50.8mm, can be equipped with a special laser pen).

Software: EagleWorks CAD/CAM and EaglePrint print driver, compatible with Windows 7/8/10. 100% support LightBurn software.

Machine/PC Connection: USB / FLASH / LAN

Operating Mode: Cutting / Engraving / Combined

Control Interface: True Color TFT LCD panel with function buttons.

Memory Capacity: Multiple job storage up to 128M.

Resolution: Up to 4064 DPI.

Motion System*: Transmission with belt on advanced balanced bearing rails.

Driven by stepper / servo motors.

Accessories: Air assist pump, industrial chiller and exhaust blower included.

Electrical Requirement*: 220V/50Hz, single phase, up to 2.5kW~4.5kW depends on configurations.

Size: 75″ x 67″ x 43″ (1900 x 1700 x 1100mm)

Net Weight: 880lb (400Kg)Issue rendering sage

The X-1309 CO2 laser cutting machine, with 51″ x 35″ (1300 x 900mm) working area, features a powered up and down working table with 8″ (200mm) adjustable space, offers an economical solution for general purpose, high quality cutting and engraving of acrylics, cardboard, wood, textiles, two-color sign laminate, stone, and much more. Eagle laser machines are the most robust, accurate, and reliable on the market.

• Full Pass-Through Capability

• Robust, High-Precision Slides

• Superior Mirrors and Mirror Mounts -

Eagle H-1610 Laser Cutting Machine

GM-EAG-H1610Eagle laser cutting machines are designed with user convenience and flexibility in mind. Hardware and software are integrated in a complete, ready-to-use package with many features that enhance usability and profitability.

Note: All features marked with * depend on configurations of the laser machine.

• Multiple laser cutting/engraving heads

• Choice of focusing lens*

• Air assist mechanism

• Camera tracing

• Front panel display and controls

• Reliable off-line operation and hot restart

• Design and machine control software

• 100% compatible with LightBurn software

• A commplete set of accessoriesEagle's offering includes a comprehensive, plug-and-play kit equipped with every component required to kickstart your machinery without delay.

An industrial-grade water chiller of superior quality propels a cooling stream through the laser tube, guaranteeing a consistent and reliable power output from the laser.

A robust exhaust system creates a vacuum within the machine’s housing, facilitating the effective removal of particulates and vapors from the cutting area.

Included in the package is the complete ducting system necessary for external venting of the machine.

Simply assemble the components, and you’ll be all set to commence your inaugural project!

• High performance motors

• Superior laser sources

• High quality optics

• Superior mirrors and mirror mounts

• Safety and reliabilityWith stepper motors from world’s leading supplier, the laser head can move very fast at extremely high resolution. In arbitrary-direction laser cutting, the head can accelerate at 2m/s2 (0.2G), while for X-axis scanning during laser engraving, acceleration up to 10m/s2 (1G) is possible.

Working Area: 63″ x 39″

Max. Workpiece Height: 1-1/4″

Laser Source: CO2 Sealed Glass Laser Tube

Laser Power: 150W

Laser Configuration: Dual lasers

Focus Lens*: Standard 2.5″, optional 4″

Electrical Requirement: 220V/50Hz, single phase, up to 4.5kWMachine/PC Connection: USB / FLASH / LAN

Operating Mode: Cutting / Engraving / Combined

Control Interface: True Color TFT LCD panel with function buttons.

Memory Capacity: Multiple job storage up to 128M.

Motion System: Transmission with belt on advanced balanced bearing rails. Driven by stepper motors.

Accessories: Air assist pump, industrial chiller and exhaust blower includedElectrical Requirement: 220V/50Hz, single phase, up to 4.5kW.

Software

RDWorks CAD/CAM, compatible with Windows 7/8/10. 100% support LightBurn software.

RDVision / RDCMarkVision CAM for the camera tracing system.Issue rendering sageThe H-1610 CO2 laser cutting machine, with 63″ x 39″ working area, fixed working table, offers an economical solution for 60″ sheet material cutting and engraving of acrylics, cardboard, wood, textiles, two-color sign laminate, stone, and much more. Eagle laser machines are the most robust, accurate, and reliable on the market.

• Camera tracing

• Air assist mechanism

• Front panel display and controls -

Eagle FiberMark F1 Laser Marking Machine

GM-EAG-FMF1Working Area*: Standard 4.3″ x 4.3″ (110 x 110mm), optional 3″ x 3″ (75 x 75mm), 7″ x 7″ (175 x 175mm) or 8″ x 8″ (200 x 200mm). Top cover can be removed to fit big or long work pieces.

Working Table: Aluminum plate table with an array of threaded holes for aligning or fixing work pieces.

Laser Source: Fiber Laser

Laser Power*: 30W / 50W

Software: EzCAD CAD/CAM, compatible with Windows 7/8/10.

Machine/PC Connection: Integrated industrial PC.

Control Interface: Direct control in software.

Motion System: Extremely fast galvo motion system.

Accessories: Rotary included.

Electrical Requirement: 220V/50Hz, single phase, up to 0.6kW.

Size: 35.4″ x 35.4″ x 59″ (900 x 900 x 1500mm)

Net Weight: 350lb (160Kg)Issue rendering sage

The FiberMark F1 laser marking machine, which is an all-in-one, plug and play, and extremely fast galvo marking system, offers an economical solution for fast and high quality laser marking of metal, plastics and more. Eagle laser machines are the most robust, accurate, and reliable on the market.

• All-In-One Design

• Adjustable Marking Area

• Rotary Unit -

Eagle FiberMark F2 Laser Marking Machine

GM-EAG-FMF2Working Area*: Standard 4.3″ x 4.3″ (110 x 110mm), optional 7″ x 7″ (175 x 175mm).

Working Table: Aluminum plate table with an array of threaded holes for aligning or fixing work pieces.

Laser Source: Fiber Laser

Laser Power*: 30W / 50W

Software: EzCAD CAD/CAM, compatible with Windows 7/8/10.

Machine/PC Connection: No computer included. Connected by USB.

Control Interface: Direct control in software.

Motion System: Fast galvo motion system.

Accessories*: Optional rotary.

Electrical Requirement: 220V/50Hz, single phase, up to 0.3kW.

Size: 34″ x 21″ x 28″ (860 x 530 x 710mm)

Net Weight: 110lb (50Kg)Issue rendering sage

The F2 offers a low-cost, high-quality solution for businesses transitioning from more traditional means of engraving, etching, and surface marking all types of metal, stone, and tile. Commonly used by custom awards and serialized part manufacturers alike, the open working area design and lightning-quick galvo system offers a cost-effective and highly efficient solution to all your etching and engraving needs.

• Focusable red dot indicators

• Adjustable marking area

• Visible red dot laser tracing