”The new RMGT 9 of Al-size offset presses handles various print jobs with exceptionally high performance. Joining the proven 920 model with its extensive lineup, including convertible perfectors in up to ten colors, the 970 model is designed to accommodate an even wider range of jobs. This model is capable of running sheet sizes up to a maximum of 940 mm in width with a 930 mm wide printing image area and has successfully adopted many of the sophisticated functions found in the flagship RMGT 10. The high-speed separator, automatic nip checking function, and a host of other performance-enhancing features ensure that the RMGT 9 continues to deliver consistently high productivity.

“The entire industry suffered a loss when drupa was cancelled,” states Kian Hemmen, Director of Sales for Print & Finishing Solutions. “RMGT’s planned launch of the new 970 was a key step forward in our continuing leadership of the 8-UP market. The decision to launch now without the drupa push is a welcomed step and we can’t wait to see the RMGT 970 landing stateside. Growing our sheet size to the popular 25” x 38” format and adding RMGT’s new ASAP System will set the 970 apart from other players in this market segment. As we have since 2008, LED-UV curing will continue to play a major role in our customer’s success.

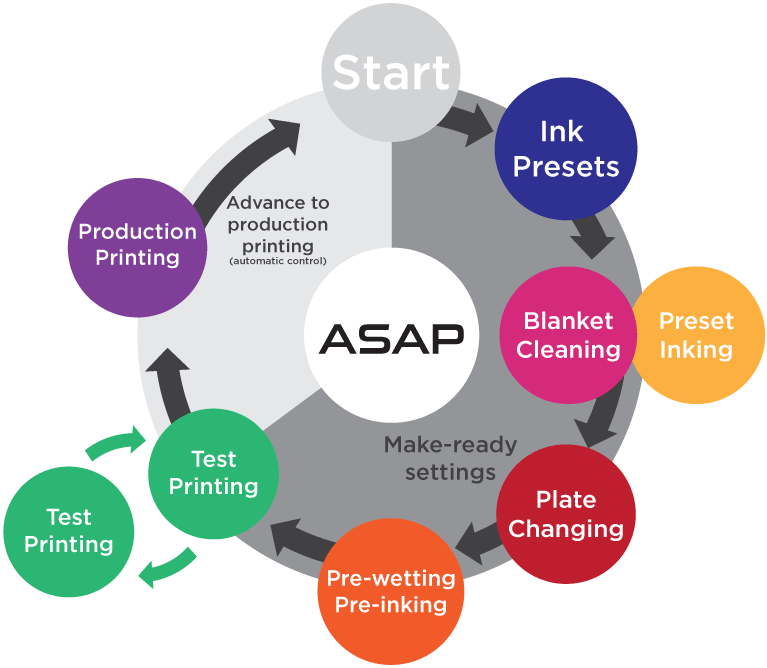

The ASAP System

Automated Smart Assist Printing increases press operating rates for continuous printing of short-run work

Smart Insta.Color technology has proven itself with fast makeready times for many years, and the release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

With ASAP the pressman touches one button and the entire printing process—from ink and paper presetting, blanket and impression cleaning, and plate changing through verification of test printing, register adjustment, ink density adjustment, and full sheet inspection are all autonomously processed by the ASAP system without even pulling a sheet.

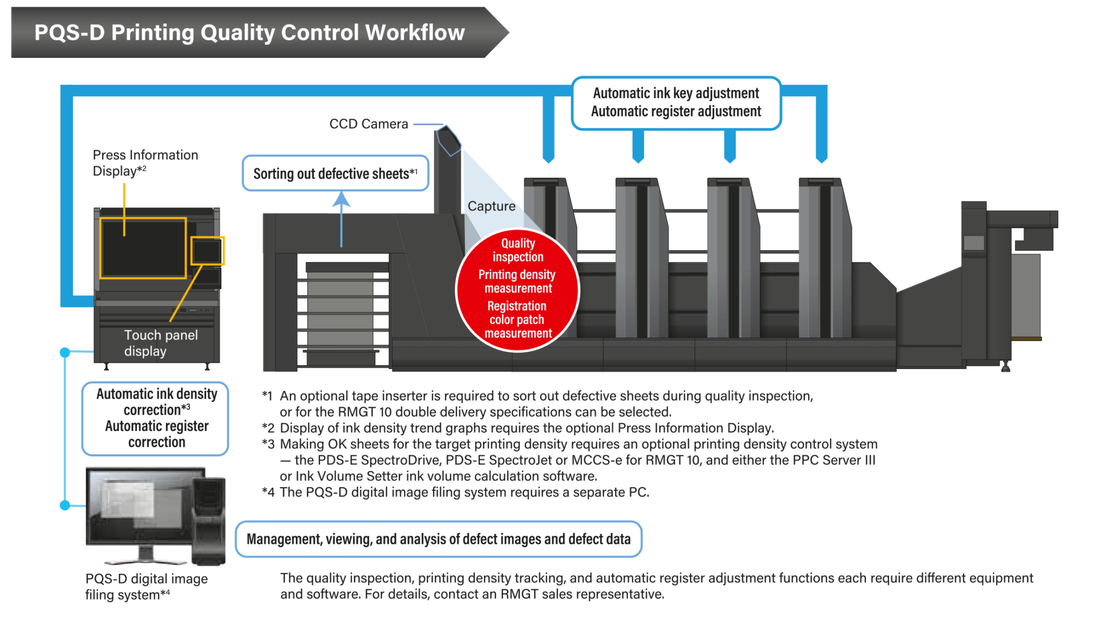

PQS-D (I+C+R) Print quality control system

Quality inspection function + Printing density function + Automatic register adjustment function

From commercial printing and very short run digital-like runs to packaging printing, RMGT’s PQS-D system uses a high-precision in-press CCD camera to inspect each printed sheet with superior reliability. The PQS-D eliminates the need to pull out sample sheets during the run and defective sheets are automatically sorted out, enhancing quality assurance and further automating printing.

The multifunction PQS-D system lets you perform 3 key functions in-press with a single camera (per side of sheet). The scanning process can be archived to provide back up quality control data to a printer’s end user.

The beauty of the PQS-D (I+R+C) system is that the three functions detailed below are ALL processed at the same time, dramatically compressing the makeready time and allowing an RMGT pressman to focus on higher production.