-

Horizon AF-408/TV-406F Small-Format Folder

GM-HOR-AF408_TV406F

The AF-408/TV-406F small-format folder is a fully automated, 8-buckle folder with an operator-friendly, automated setup that can manage a wide range of simple or complex fold patterns, especially for the insert and pharmaceutical markets. The system can run at up to 590 fpm, and the suction head can run up to 30,000 cycles per hour.

- Job storage: The system’s memory can store up to 200 fold patterns for quick and easy setup of simple and repeat jobs.

- Easy setup: A new scoring navigator assists with the quick and accurate setup of scoring and perforation positions

- Full automation: Each section of the folder is set automatically via the improved color touchscreen controls, and separate feed and delivery counters provide accurate piece production for critical jobs like pharmaceutical inserts.

- Application flexibility: Two fold plates in the initial folding section expand the number of folds that can be performed prior to cross-folding or when running the TV-406F right angle section in parallel.

Sheet Size Max: 16.92″ x 25.98″

Min: 1.97″ x 3.94″Sheet Weight Range Coated: 73 to 157 gsm

Uncoated: 33 to 157 gsmBelt Speed Up to 590 fpm Production Speed Suction head 30,000 cycles/hour Issue rendering sage

The AF-408/TV-406F small-format folder is a fully automated, 8-buckle folder with an operator-friendly, automated setup that can manage a wide range of simple or complex fold patterns, especially for the insert and pharmaceutical markets.

• Easy setup

• Various checking functions

• Application flexibility

-

Horizon AFC-746F B1 Pallet-Feed Folder

GM-HOR-AFC746F_B1

The Standard Horizon AFC-746F B1 Pallet-Feed Folder includes advanced set-up automation through a user-friendly color touch-screen control panel that displays all common fold formats and sheet sizes for easy selection.

- Fully automated adjustments: The folder features quick changeover and fully automated setup with up to 47 automated adjustments including in-feed, roller gap, buckle fold, and knife-fold sections.

- Unparalleled fold flexibility: The AFC-746F has 6 buckle plates and handles sheet sizes up to 29.1” x 43.3” and as small as 8.27” x 11.695”. The system also offers 20 pre-set fold patterns with a programmable memory for up to 200 different jobs.

- Improved slitter shaft removal: The AFC-746F includes a 47″ pallet pile feeder with suction head and a new, ergonomically friendly slitter shaft removal system which allows the operator to remove the perforation shaft automatically for easier blade setting.

Maximum Sheet Size 29.1″W x 43.3″L Minimum Sheet Size 8.27″W x11.695″L Stock Weight Range 35 to 209 gsm (uncoated paper) Maximum Pile Height 47.2″ (pallet included) Issue rendering sage

The Standard Horizon AFC-746F B1 Pallet-Feed Folder includes advanced set-up automation through a user-friendly color touch-screen control panel that displays all common fold formats and sheet sizes for easy selection.

• User-friendly

• Advanced automation

• Superior folding quality

-

Horizon AFV-566F/TV-564 Folder

GM-HOR-AFV566F

The Horizon AFV-566/TV-564 Folder is a highly automated and dynamic machine that achieves new levels of production efficiency in folding.

- Simple touchscreen setup: Advanced automation reduces setup time and allows easy operation via color touchscreen.

- Unique buckle plate: The uniquely designed buckle plate ensures consistent, accurate folds, and accommodates a wider range of substrates.

- Dynamic folding: Optional dynamic folding is available to change fold patterns on the fly for variable signatures with no blank sheets in the set.

- The system also features automatic scoring navigation and double-sheet detection, improved registration, and easier sheet loading.

Maximum Sheet Size 22.05″W x 35.43″L Minimum Sheet Size 4.13″W x 5.83″L Belt Speed 30 to 270 meters/min Issue rendering sage The Horizon AFV-566/TV-564 Folder is a highly automated and dynamic machine that achieves new levels of production efficiency in folding.

The Horizon AFV-566/TV-564 Folder is a highly automated and dynamic machine that achieves new levels of production efficiency in folding.

• Simple touchscreen set up

• Unique buckle plate

• Dynamic folding

-

Horizon AFV-566FKT Folder

GM-HOR-AFV566FKT

The automated AFV-566FKT Folder is a 6-buckle folder with integrated knife/buckle cross-folding that contains 44 fully-automated settings for improved efficiency, more operator-friendly production, and reduced waste and make-ready. Roller gaps and buckle plates can be easily fine-tuned from the improved touchscreen control panel, and automated stop adjustment under the knife and trailing edge roller adjustments reduce operator intervention and maximize machine uptime.

- Fast setup: Setup and changeover times are nearly 20% faster than the previous generation of folder

- System status indicators: The AFV-566FKT features customizable LED lights that alert operators to system status at a glance.

- Reduced noise: Enhanced sound-proof covers are included over the fold plates and the registration table to reduce noise by 2 decibels compared to previous models.

- Improved feed section: The AFV-566FKT uses a single-piston suction head system for faster and more accurate operation.

- New registration: The system features an automated register table with an adjustable vacuum belt that eliminates steel and plastic drive pull-in for registration.

- No trial-and-error: The AFV-566FKT can automatically calculate the optimal feed interval to ensure top production speeds and efficiency with no manual adjustments.

- Production speeds: The system can reach speeds of up to 656 feet/min with cross-folding and up to 885 feet/min for parallel folds.

Maximum Sheet Size 29.1″W x 43.3″L Minimum Sheet Size 8.27″W x11.695″L Stock Weight Range 35 to 209 gsm (uncoated paper) Maximum Pile Height 47.2″ (pallet included) Issue rendering sage

The automated AFV-566FKT Folder is a 6-buckle folder with integrated knife/buckle cross-folding that contains 44 fully-automated settings for improved efficiency, more operator-friendly production, and reduced waste and make-ready.

• Easy setup

• Advanced automation

• Application flexibility

-

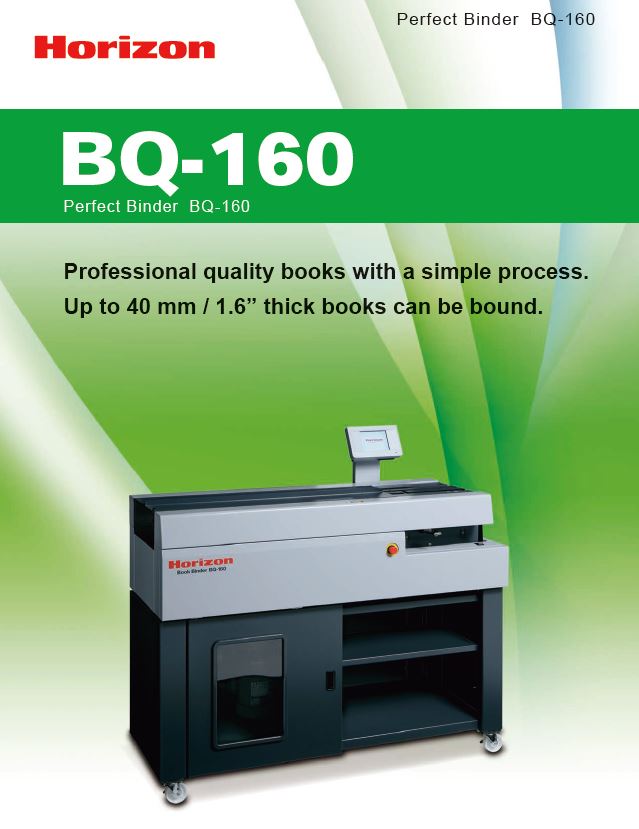

Horizon BQ-160 Perfect Binder

GM-HOR-BQ160

The Horizon BQ-160 Single-clamp Perfect Binder is equipped with an intuitive, icon-based color touchscreen for fingertip adjustment of key parameters. This “intelligent automation” feature is built into all Horizon post-press products. With single-person operation, the BQ-160 can produce three popular types of binding: perfect binding, tape binding and pad binding – at speeds up to 180 cycles per hour with books up to 1.1” thick. The BQ-160 is specifically designed for cut sheet applications. Other advantages include an electric book clamp, two-way notching, an efficient paper dust vacuum system, nipper height and tilt adjustment from the touchscreen, and a dynamic nipper table for auto book sizing.

Easy-to-use touchscreen controls: A dynamic color touchscreen allows the operator to easily adjust a range of settings including cover alignment with the spine, nipping pressure, clamping pressure, and much more.

High-quality books: The BQ-160 can produce extremely strong, high quality perfect bound books up to 1.6” thick at speeds up to 180 cycles per hour and can handle light to moderate production needs in almost any environment.

Other key features: Other features on the BQ-160 include energy-save and auto-off functions, the ability to notch in one or both directions, and an optional carbon air filtration system to reduce adhesive odors.

Adding a cover: The BQ-160 Binder can be put in-line with the CRB-160 Cover Creaser, which is setup through the color touchscreen on the BQ-160. The scoring position is set automatically according to the book thickness input into the BQ-160.The CRB-160 scores up to 150 lb. laminated covers, and a wide variety of scoring patterns can be selected from the touchscreen.

Standalone cover creaser: A standalone CRB-160 model is also available with an integrated color touchscreen, and it is ideal for creasing covers, restaurant menus, greeting cards and other digital print applications.

Book Size Max 350 x 300 mm (13.77″ x 11.81″) Book Size Min 70 x 128 mm (2.76 x 5.04″) Book Thickness 1 to 40 mm (0.04″ to 1.57″) Cover Size Max 350 x 640 mm (17.77″ x 25.19″) Cover Size Min 70 x 256 mm (2.76″ x 10.08″) Cover Weight Range 82 to 302 gsm (22 to 80 lb) Production Speed Max 180 cycles/hr Issue rendering sage The Horizon BQ-160 Single-clamp Perfect Binder is equipped with an intuitive, icon-based color touchscreen for fingertip adjustment of key parameters.

The Horizon BQ-160 Single-clamp Perfect Binder is equipped with an intuitive, icon-based color touchscreen for fingertip adjustment of key parameters.

• Binding thickness: up to 1.1”

• Cycle speed up to 180 books/hr

• Book dimensions from 5.8 x 4.1” - 11.8 x 15.7”

• Spine preparation includes roughing & notching

• PUR capabilities: Model BQ-160PU -

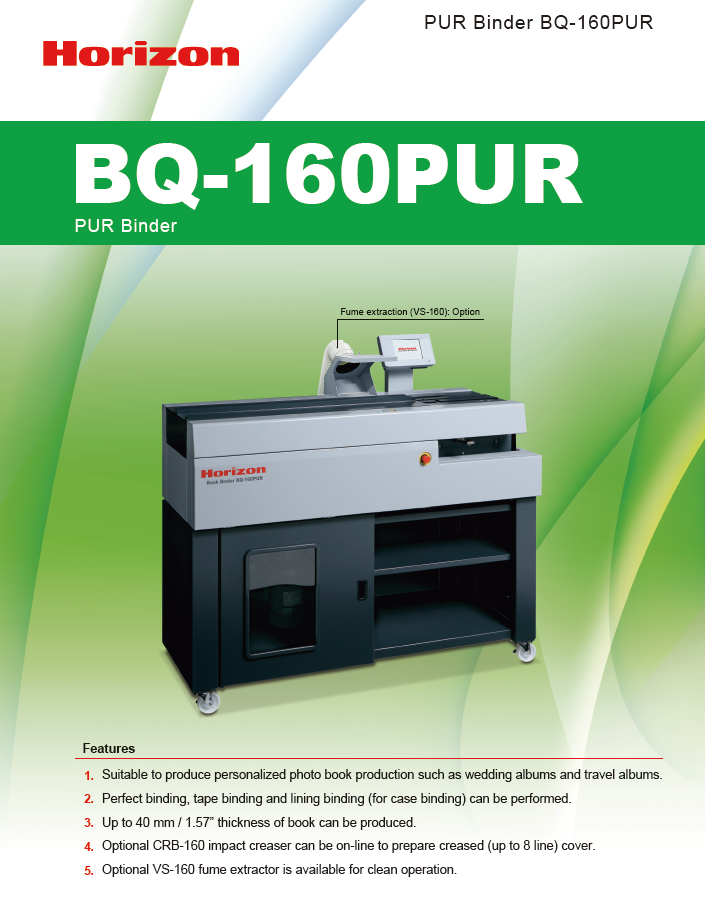

Horizon BQ-160 PUR Perfect Binder

GM-HOR-BQ160PUR

The Standard Horizon BQ-160 PUR Single-clamp Perfect Binder produces professional-quality books with a simple and efficient binding procedure, and the binder is also capable of padding and tape binding.

- PUR Perfect Binder: For more information about PUR binding, click here.

- Easy-to-use touchscreen controls: A dynamic color touchscreen allows the operator to easily adjust a range of settings including cover alignment with the spine, nipping pressure, clamping pressure, and much more.

- High-quality books: The BQ-160 can produce extremely strong, high quality perfect bound books up to 1.6” thick at speeds up to 180 cycles per hour and can handle light to moderate production needs in almost any environment.

- Other key features: Other features on the BQ-160 include energy-save and auto-off functions, the ability to notch in one or both directions, and an optional carbon air filtration system to reduce adhesive odors.

- Adding a cover: The BQ-160 Binder can be put in-line with the CRB-160 Cover Creaser, which is setup through the color touchscreen on the BQ-160. The scoring position is set automatically according to the book thickness input into the BQ-160.The CRB-160 scores up to 150 lb. laminated covers, and a wide variety of scoring patterns can be selected from the touchscreen.

- Standalone cover creaser: A standalone CRB-160 model is also available with an integrated color touchscreen, and it is ideal for creasing covers, restaurant menus, greeting cards and other digital print applications.

Book Size Max 350 x 300 mm (13.77″ x 11.81″) Book Size Min 70 x 128 mm (2.76 x 5.04″) Book Thickness 1 to 40 mm (0.04″ to 1.57″) Cover Size Max 350 x 640 mm (17.77″ x 25.19″) Cover Size Min 70 x 256 mm (2.76″ x 10.08″) Cover Weight Range 82 to 302 gsm (22 to 80 lb) Production Speed Max 180 cycles/hr Issue rendering sage

The Standard Horizon BQ-160 PUR Single-clamp Perfect Binder produces professional-quality books with a simple and efficient binding procedure, and the binder is also capable of padding and tape binding.

• Easy-to-use touchscreen controls

• Up to 180 cycles per hour

• Energy-save and auto-off functions -

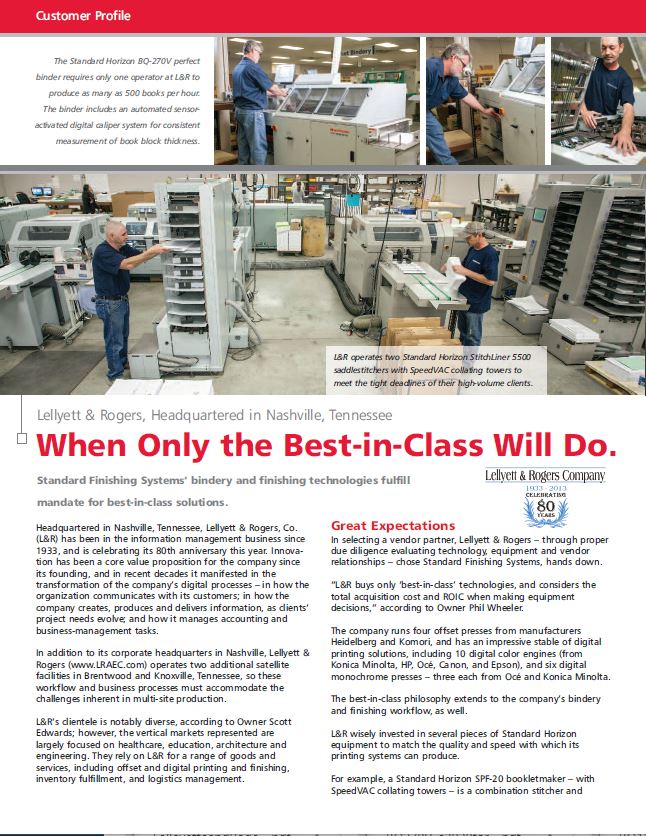

Horizon BQ-270V Perfect Binder

GM-HOR-BQ270V

The BQ-270V single-clamp binder offers high-quality production perfect binding with fully automated operation, push-button simplicity, and on-demand production of variable thickness books. Includes an automated, sensor-activated digital caliper system which consistently measures book block thickness and automatically transfers this data to the binder for quick, automated set-up with no cycle lag time for books of different thicknesses.

Watch the BQ270V work with Horizon's newest Integrated Robotic Arm Technology! The Robot Book Block Feeding System transfers book blocks from the Horizon HOF-400 High Speed Sheet Feeder into the BQ270V Perfect Binder, reducing human labor costs while increasing efficiency.

- Automated setup: The binder includes an automated, sensor-activated digital caliper system which consistently measures book block thickness and automatically transfers this data to the binder for quick, automated set-up with no cycle lag time for books of different thicknesses.

- Designed for print-on-demand: Designed to meet the needs of the short-run, print-on-demand book market, the BQ-270V also features single-person production of up to 500 books per hour.

- Other key features: automatic air-suction cover feeding with in-line scoring, a large 10.4″ intelligent color touch-screen, job programming, and a compact configuration.

Book Size Max 320 x 320 mm (12.59″ x 12.59″) Book Size Min 135 x 105 mm (5.32″ x 4.14″) Book Thickness 1 to 50 mm (0.04″ to 2.00″) Cover Size Max 320 x 660 mm (12.59″ x 25.98″) Cover Size Min 135 x 230 mm (5.32″ x 9.06″) Cover Weight Range 82 to 302 gsm Production Speed Max 500 cycles/hr Issue rendering sage The BQ-270V single-clamp binder offers high-quality production perfect binding with fully automated operation, push-button simplicity.

The BQ-270V single-clamp binder offers high-quality production perfect binding with fully automated operation, push-button simplicity.

• Integrated Robotic Technology

• Cycle speed: 500 books/hr

• Book dimensions: 5.9 x 4.2” - 12.5 x 12.5”

• Spine prep: roughing, notching & milling

• PUR Capabilities: Model BQ-280PUR -

Horizon BQ-280PUR Perfect Binder

GM-HOR-BQ280PURSpace Saving, High Quality, Single Clamp PUR Perfect Binder

- PUR Perfect Binding: High quality PUR binding is assured with dual application drums and separate EVA / PSA side glue application. Drum application enables production of one to one variable thickness books with maximum quality control.

- Extended spine length: Maximum book size is 385 x 320 mm / 15.15" x 12.59" and the maximum book thickness is 51 mm / 2".

- Variable thick production: Built in thickness caliper provides greater production efficiency for instant changeover and variable thickness book production. The BQ-280PUR provides unsurpassed production efficiency in a single clamp binder.

- EVA Glue: Low temperature EVA glue (140 °C / 284 °F or below) can be used. The system can be used for both PUR and EVA with the same tank.

- JDF Workflow: The system can be further enhanced with Horizon's pXnet bindery control system which integrates JDF workflow from upstream devices.

Book Size Max 385 x 320 mm (15.15″ x 12.59″) Book Size Min 135 x 105 mm (5.32″ x 4.14″) Book Thickness 1 to 51 mm (0.04″ to 2.00″) Cover Size Max 385 x 660 mm (15.15″ x 25.98″) Cover Size Min 135 x 225 mm (5.32″ x 8.86″) Cover Weight Range Normal: 82 to 302 gsm | Coated: 105 to 349 gsm Production Speed Max 500 cycles/hr Issue rendering sage Horizon’s BQ-280PUR Perfect Binder is specially designed to handle the unique requirements of digital print – with digital print friendly processing, quick set-up and changeover for shorter production runs, book-of-one capability, and even in-line verification for document integrity.

Horizon’s BQ-280PUR Perfect Binder is specially designed to handle the unique requirements of digital print – with digital print friendly processing, quick set-up and changeover for shorter production runs, book-of-one capability, and even in-line verification for document integrity.

• PUR Perfect Binder

• Easy to use touch screen controls

• Precision caliper system

• Store jobs for quick set-up

• Designed for print-on-demand -

BQ480 PERFECT BINDER (EVA)

GM-HOR-BQ480

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop, and also accommodates the lowest temperature setting for PUR glue. Interchangeable PUR and EVA glue tanks.

- PUR-friendly design: Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop and accommodates the lowest temperature setting for PUR glue.

- Easy glue changeover: The BQ-480 also features interchangeable glue tanks to switch easily between PUR and EVA glue.

- Automated controls: The binder also offers advanced automation through a movable color touchscreen including adjustments for roller height, nipping height, and amount of side glue.

Issue rendering sage The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

• Book Block Size: 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hr -

BQ-480 PERFECT BINDER (PUR)

GM-HOR-BQ480PUR

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a mere 5mm drop, and also accommodates the lowest temperature setting for PUR glue. Interchangeable PUR and EVA glue tanks.

• Book Block Size from 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hrIssue rendering sage The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

The Horizon BQ-480 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one. Interchangeable PUR and EVA glue tanks.

• Book Block Size from 5.71” x 4.14” – 12.59” x 12.59”

• Book Thickness: 0.04” to 2.56”

• Book of One Production-Max. 800 book/hr

• Cover Weight Range: Up to 348.9gsm

• Cycle Speed: 1,350 cycles/hr -

Horizon BQ-500 Perfect Binder

GM-HOR-BQ500The BQ-500 perfect binder is designed for increased book-of-one productivity, increased automation, and increased quality control over a wider range of substrates regardless of run length. The BQ-500 is the first perfect binder to come equipped with iCE LINK, Horizon’s new cloud-based JDF workflow and job-management tool. The system features an improved and easy-to-use 12.1” touchscreen for quick setup, an ergonomic design for efficient, operator-friendly operation, and an enhanced delivery system for thin books.

- Advanced automation: The BQ-500 features 21 automated sections in total, reducing setup and changeover time even when making fine variable thickness adjustments – all while ensuring higher quality books.

- Improved visual monitoring: A new, larger production monitoring screen and new, customizable LED lighting serve as a quick-look indicator of system readiness and status. Indicator lights can even be seen from across the production floor with the BQ-500’s light tower.

- Variable production: The BQ-500 is the most productive binder for book-of-one production in its class. In a variable range of +/-5mm, the BQ-500 can reach production speeds of up to 800 books per hour, almost double the productivity of other binders in this range.

- Expanded customization: The BQ-500 is designed to support a wide range of connectivity and enhancement options so that you can expand and tailor capabilities to match your unique needs.

- Clean spine preparation: Improved milling waste removal, a newly designed air flow, and an improved glue application system help ensure high-quality production.

- EVA and PUR: The BQ-500 features interchangeable EVA and PUR glue tanks with a new and improved tank removal process for cleaner and easier tank changeover.

- Gentle delivery: To prevent damage to more delicate books, the BQ-500 has reduced the book drop from 150mm to only 5mm. Books are then gently lowered to the delivery belt.

- iCE LINK: The BQ-500 is the first perfect binder to come equipped with iCE LINK, a cloud-based platform that can provide device monitoring, KPI analysis, PM schedule/alerts, JDF/JMF Workflow, scheduling, job creation, editing and more.

Book block Max: 12.59″ x 12.59″

Min: 5.70″ x 4.13″Cover size Max: 12.59″ x 26.37″

Min: 5.315″ x 8.859″Cover pile height 5.90″ Thickness Max: 2.55″

Min: 0.039″Cover thickness Coated: 104 to 348 gsm

Uncoated: 81.4 to 302 gsmProduction Speed(s) Up to 800 books/hr Issue rendering sage The BQ500 is designed to increase book-of-one productivity, increase automation, and quality control over a wider range of substrates.

The BQ500 is designed to increase book-of-one productivity, increase automation, and quality control over a wider range of substrates.

• Supports both EVA and PUR

• Produce high speed and high quality books without a skilled operator

• Up to 1,350 cycles per hour

• 12.1" user friendly touch screen -

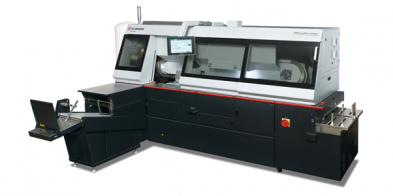

Horizon CABS 6000 Perfect Binding System

GM-HOR-CABS_6000The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding. The system includes the MG-600 Gatherer, SB-17 seventeen-clamp Perfect Binder, and a HT-110 Three-knife Trimmer. The system can produce up to 6,000 books/hour.

Key features: An in-line stacker for stand alone gathering, twin milling stations, automated in-line cover scoring, gauze feeding for hard cover book blocks, and advanced quality control features such as CCD cameras, digital caliper thickness detection, and weight checking.

Easy glue changeover: The CABS 6000 is equipped with quick-change EVA and PUR glue tanks that slide out on rails to a wheeled trolley. Operators can easily changeover from one binding style to another in about 5 minutes.

Cutting and trimming: The HT-110 Three-knife Trimmer produces trimmed books from 5.71” x 4.05” to 14.4” x 11.81”.

Book Size Max (Landscape) Off-line: 400 x 280 mm (15.74″ x 11.02″) / In-line: 385 x 275 mm (15.15″ x 10.82″) Book Size Min (Landscape) Off-line: 148 x 105 mm (5.83″ x 4.14″) / In-line: 148 x 105 mm (5.83″ x 4.14″) Book Size Max (Portrait) Off-line: 330 x 320 mm (12.99″ x 12.59″) / In-line: 250 x 320 mm (9.84″ x 12.59″) Book Size Min (Portrait) Off-line: 135 x 185 mm (5.32″ x 7.29″) / In-line: 135 x 185 mm (5.32″ x 7.29″) Book Thickness 2 to 50 mm (0.08″ to 2″) Cover Size Max 400 x 660 (15.74″ x 25.98″) Cover Size Min 135 x 220 mm (5.32″ x 8.67″) Cover Weight Range Normal: 81.2 to 303 gsm / Coated: 104.4 to 348 gsm Production Speed Max 6,000 books/hr Issue rendering sage The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding.

The innovative Standard Horizon CABS 6000 perfect binding system is bringing new levels of automation to production bookbinding.

• in-line stacker for stand alone gathering

• Twin milling stations

• Automated in-line cover scoring

• Advanced quality control features