- Home /

Categories:

Filter Results

- Manufacturer

-

- Preferred Pack

- Vivid Matrix

- Screen

- MBM (5016)

- Challenge (4907)

- Morgana (1554)

- MGI (187)

- Mimaki (114)

- Akiles (35)

- Horizon (34)

- OKI (34)

- FastBind (10)

- Graphic Whizard (10)

- RMGT (Ryobi Mitsubishi Graphic Technology) (10)

- Formax (9)

- Rhin-O-Tuff (9)

- Martin Yale (8)

- JBI (6)

- Fujipla (2)

- Tamerica (2)

- Amerilam (1)

- Bauman (1)

- GBC (1)

- Lithec (1)

- Perfecta (1)

- Mitsubishi (1)

- Pamarco (1)

- IntoPrint (42)

- Afinia Label (42)

- CUTWORX (19)

- En-Press (14)

- Foliant (12)

- Summa (9)

- Xante (8)

- Graphic finishing partners (7)

- Micron (7)

- KODAK (6)

- GU Eagle (5)

- TEC Lighting (4)

- Powis (3)

- KAMA (2)

- Valiani (2)

- Baum (1)

- Lami (1)

- Sub Categories

-

Matrix Omni-Flow 330 (SRA3) Deep Pile Feeder

GM-CWT-OMNI330The Matrix Omni-Flow Deep Pile Feeder is a modular system that is designed to be simple to install, configure and operate. The feeder can be retro-fitted to any Matrix Pneumatic or Matrix Duplex model.

• Retrofits all Matrix pneumatic and duplex models

• Quick and easy set-up and operation

• Fully automatic lamination and foiling

• Change between paper stocks in seconds > Learn More -

Preferred Pack CT-50BHO: 2" Top & Bottom Carton Sealer

GM-PPS-CT_50BHOThe Preferred Pack CT-50-BHO light duty carton sealer is simple to use. The machine applies a 2 inch tape strip to the bottom of the carton. The CT-50-BHO can be easily adjusted in only seconds to process a different size carton. Excellent for low profile, small, lightweight boxes.

• 2 Side Drive Belts - Positive Feed

• Heavy Duty Locking Casters

• Fully Adjustable Legs

• In-feed Conveyor

• Exit Conveyor > Learn MoreUS$3,445.00 -

Preferred Pack CT-50: 2" Top & Bottom Carton Sealer

GM-PPS-CT_50The Preferred Pack CT50 light duty carton sealer is simple to use. Semi-automatic sealer with side drive belts for positive feed and side pressure rollers to close box top. Excellent for low profile, small, lightweight boxes.

• “Piranha” Tape Head with “Easy Thread”

• Interchangeable Tape Heads

• Fully Adjustable Legs

• Min/Max box height: 5" to 20"

• Min/Max box width: 4.7" to 20" > Learn MoreUS$3,449.00 -

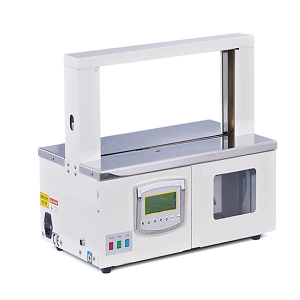

Large Capacity Banding Machine (30mm tape width)

GM-PPS-PP02_30• Package Width: 1.2" - 18". Height: 7.5"

• PCB with keyboard

• Uses paper or plastic tape. 30mm

• Tape length: 500 ft rolls

• Speed: up to 26 PPM

• Power:110 volt > Learn MoreUS$6,800.00 -

Matrix 370 Pneumatic Laminator

GM-VLT-MX370P

The Matrix MX-370P SRA3 Pneumatic single-sided laminating, digital foiling and special effects system. Create eye-catching finishes using foil and special effects with the pneumatic option, achievable with adjustable pressure rollers.

• Semi-automatic feed

• Pneumatic pressure

• Anti-curl technology

• Automatic separator

• Multifunctional - laminate, foil & create spot UV-style effects > Learn More -

Small Duty Banding Machine (Open)

GM-PPS-TZ_888• Package Width 1.5"- 9.5". Height: 1/4" - 5.5"

• Uses 20, 30 or 40mm wide paper/plastic tape

• Tape Length: 500 ft rolls

• Speed: 20-25PPM

• Power: 110 volt, 50/60Hz 1 Phase"

• In Stock

> Learn MoreUS$4,495.00 -

Medium Capacity Banding Machine (Open)

GM-PPS-TZ_889• Package Width: 1.5" - 9.5". Height: 1/4" - 5.5"

• Uses 20, 30 or 40mm wide paper/plastic tape

• Tape length: 2000 ft rolls

• Speed: 20-25 PPM

• Power: 110 volt, 50/60Hz 1 Phase

• In Stock

> Learn MoreUS$4,750.00 -

Extra Large Capacity Banding Machine (50mm tape width)

GM-PPS-PP04_50• Package Width: 1.2" - 15.7". Height: 7.5"

• PLC with touchscreen

• Uses paper or plastic tape. 50mm

• Tape Length: 500 ft rolls

• Speed: up to 30 PPM

• Power 110 volt > Learn MoreUS$7,450.00 -

Screen PlateRite 8600NII Plate Maker

PM-SCR-PR8600NII

The PlateRite 8600N delivers superior imaging precision and reliable operation. It consumes less electricity and decreases material use, while meeting the varying throughput and quality demands of printing companies. These systems (available in 3 models) feature the latest fiber laser diode exposure heads, enabling them to achieve throughput of up to 32 plates per hour.

• Variable range of imaging resolutions

• Upgradeable to higher productivity

• Handles plate requirements of sheetfed and web offset presses

• Capable of imaging 2-up to 8-up plates from 12 x 14.6 inches to 45.6 x 37 inches > Learn More -

Preferred Pack PP-563BE: Semi-Automatic Carton Sealer

GM-PPS-PP_563BEThe operator simply opens up and squares a flat box, loads it into the pack station, uses the kick plate to fold minor flap and activate the bottom flap folder. The operator then presses the green switch and 2 of the bottom flaps are opened allowing for the next box to be fed into the machine. The operator then fills the box, and when once filled, the operator closes the minor and major flaps and pushes the box into the carton sealer.

• Saves time and labor costs to close bottom flaps before loading

• Folding size: L 250-500mm (10-20”)

• Folding size: W 200-400mm (8-16”)

• Folding size: H 100-500 mm (4-20”)

• Air: 1 CFM at 60 PSI

• Box Height:4 to 19.6 max Inch

> Learn MoreUS$3,500.00 -

5300 Combo Fully Automated L'Sealer & Tunnel

GM-PPS-5300COMBO

Two machines built on the same frame. This is Preferred Packaging's Best Seller with Automatic Product Adjustment.

• Combination fully automatic L’ Sealer and tunnel

• Easy load film cradle

• Fully enclosed safety doors

• Easy access control panel

• Self diagnosing Delta PLC

> Learn More -

Preferred Pack CT-55-BELT: 2" Top Bottom Carton Sealer

GM-PPS-CT_55_BELTThe Preferred Pack CT-55-26 light duty carton sealer is simple to use. The CT-55-26 applies a 2 inch tape strip to both the top and bottom of the carton simultaneously. This two belt drive design is a heavy duty versatile machine designed for dependable performance and easy operation. The CT-55-26 can be easily adjusted in only seconds to process a different size carton. Excellent for low profile, small, lightweight boxes.

• Interchangeable Tape Heads

• Top and Bottom Pressure Rollers to Close Box Top

• 2 Top and Bottom Drive Belts - Positive Feed

• Heavy Duty Locking Casters

• Fully Adjustable Legs

• Bottom Drive belts only > Learn MoreUS$3,250.00