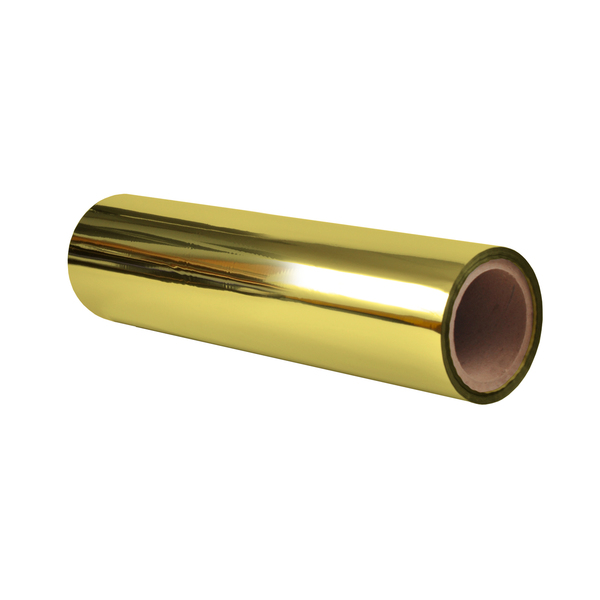

Sleeking has revolutionized traditional foil stamping, spot coating, and laminating. With a combination of adhesive foils and films that only bond to digital toner, combined with the proper heat and pressure settings on a Sleeking laminator like the Vivid Matrix. This allows printers the ability to insource not only their foil stamping and spot coating, but their laminating needs as well, boosting turn times and profit margins.

Sleeking and Laminating

The Process

Step 1: Print the background

Step 2: Apply an over-laminate. In this case we used Printable Karess to seal the background toner.

Step 3: Once laminated, the sheets are run again through the press to apply tone anywhere that the foil will be applied.

Step 4: The final step is to bond the foil, which will only adhere to the areas that have exposed toner. So with this process it enables you to do variable-data foil applications.