-

Foliant Mercury 530 NG Laminator

GM-MSC-FOL530NGThe FOLIANT Mercury 530 NG is a next generation of popular SF version. It is very compact industrial laminating machine, constructed for a heavy duty digital and offset outputs lamination. It is equipped with suction feeding head Foliant and a high speed bump separator. Several options are available for the Mercury machine – Heidelberg feeding head, Foliant Foiler, non-sticky pressure roller, pallet stacker, etc. Due to its high pressure system, format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 27 m/min., while performance is 2300 sheets per hour of B2 portrait (white paper 200 gsm).

Feeder

The FOLIANT Mercury 530 NG is equipped with a rising pile back separation stream feeder and with a suction feed head Foliant. It is driven by an Omron servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheets back airing. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 54 cm pile of paper.

Laminator

The FOLIANT Mercury 530 NG laminator maximum sheet size is 53 x 75 cm. The minimum sheet size is 32 x 25 cm (A4).The FOLIANT Mercury 530 NG machine is a single sided thermal industrial laminator, laminating the 115 – 600 gsm paper.

The laminating unit is equipped with an adjustable twin decurl unit:

With a decurl blade for offset printed sheets decurling

With a decurl roller for digital printed sheets decurling (to prevent the scratches on sheets printed on both sides by digital print with sensitive inks).The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 - 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is made between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge. The machine is fitted with OMRON Programmable Logic Controllers, which control all machines’ functions. The used PLC system includes many automation items for an easy control of the machine and a reliable lamination. The whole machine is controlled by an interactive easy understandable icon touch screen panel – no language version is needed.

Separator

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered into a vibrating jogger (optional) or a pallet stacker (optional).

Laminating Films

The machine laminates the BOPP films (24 – 42 μm) and Nylon films (24 – 35 μm). The PET films (20 – 26 μm) can be laminated with the optional module only.

Safety Measurements

FOLIANT Mercury 530NG is certified by independent testing laboratory DGUV Test and obtained GS mark ("Tested Safety"). The measurements for operators safety are better then required by law in order to minimize injuries.

Maximal Speedsingle side 27 m/min.Feeding Systemautomatic, Suction Feeder Foliant, Feeder's Capacity 54 cmOverlapsAutomatic, PLC Controlled, Overlaps Accuracy ± 2 mmSeparationAutomatic, bump rollersPaper Weight115–600 g/m²Main Roller Pressure SystemPneumaticCompressorExternal, 150 l / min, 6-8 barMinimal Sheets Size (w×l)32×25 cmMaximal Sheets Size (w×l)53×75 cmMaximal Performance2300 B2 / hod.Temperature Control80–140 °C, Warming Up Time 8 minPower Supply3 f., 400V AC, 50-60 HzPower5250 WMechanical ParametersFloorspace (w×l) 120×270 cm, Weight: 595 kgModular StandPallet Stackerintegrated automatic, Capacity ~70 cmNon-sticky pressure rollerAir ShaftIssue rendering sage

The Foliant Mercury 530 NG is a very compact industrial Laminating Machine. Constructed for heavy-duty digital and offset output. It is equipped with a Foliant integrated suction feeder and a high-speed bump separator. Several options are available: Foliant Foiler, non-sticky pressure roller, motorized pallet stacker, extended sheets laminating module, etc.

• Easy operation with touch screen interface

• Maximum speed 88 ft/minute

• 2,300 sheets p/hour of 19.7″ x 27.8″ portrait (white 200 gsm)

• Pressure is pneumatically adjustable

• De-curl blade/roller for offset/digital sheets

-

Foliant Taurus 760 NG DS Laminator

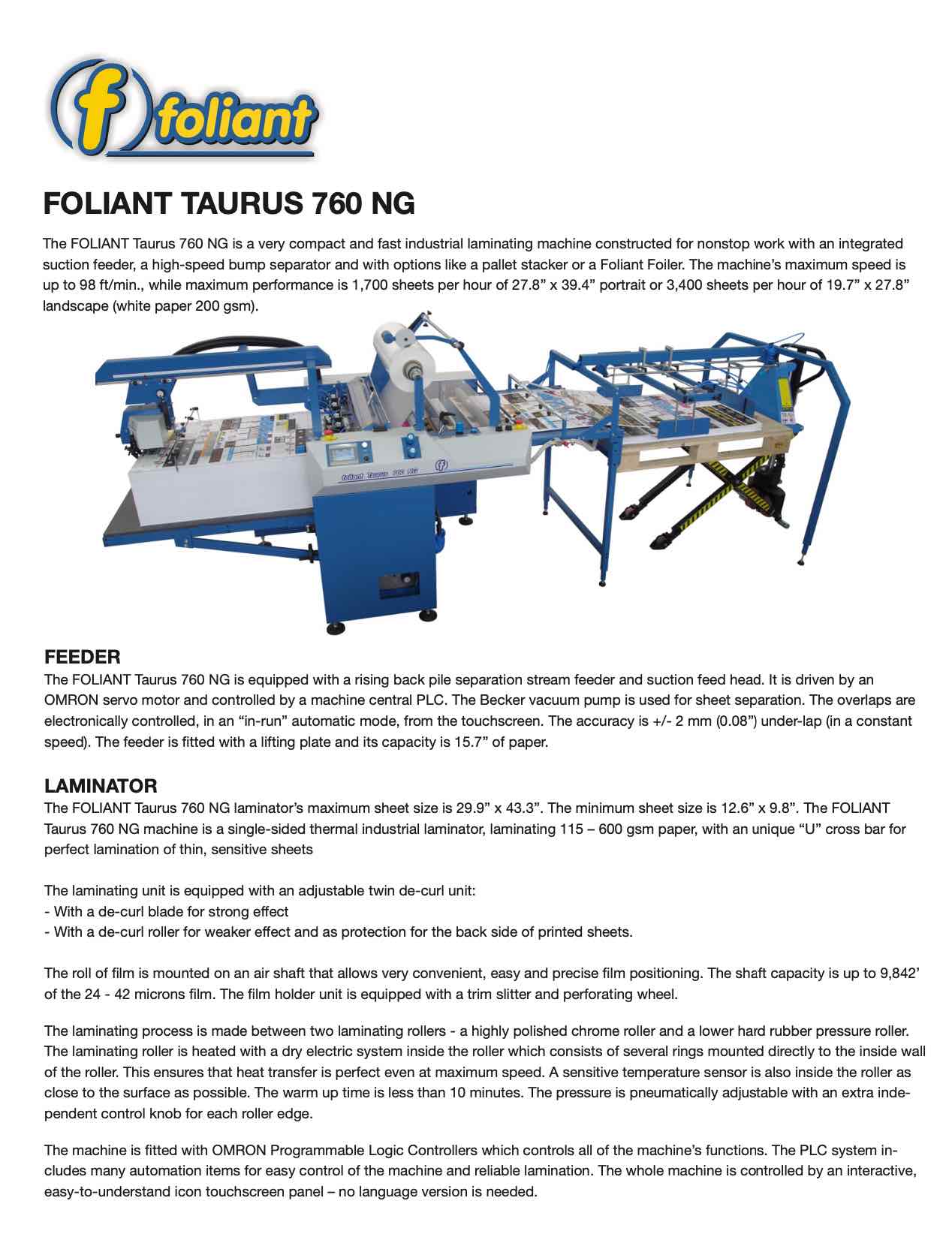

GM-MSC-FOL760NGThe Foliant Taurus 760 NG is a fast and Compact Industrial Laminating Machine, constructed for nonstop work with an integrated suction feeder and high-speed bump separator, and with options like a pallet stacker and Foliant Foiler. The machine’s maximum speed is up to 98 feet/minute, while maximum performance is 1,700 sheets per hour of 27.8″ x 39.4″ portrait or 3,400 sheets/hour of 9.7″ x 27.8″ landscape (white paper 200 gsm).

ADVANTAGES

- Easy operation

- Equipped with a rising back pile separation stream feeder with a suction feed head

- Single-sided thermal industrial laminator

- Film is mounted on an air shaft that allows convenient, easy and precise film positioning

- Film holder unit is equipped with a trim slitter and perforation wheel

- Pressure is pneumatically adjustable

- OMRON programmable logic controller for easy automation

- Optional jogger, pallet stacker, PET module, Foliant Foiler, film loader/manipulato

Maximum Speed: 98 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder’s Load Capacity: 15.7” (40 cm) Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L (32 cm x 25 cm) Maximum Sheet Size: 29.9” W x 43.3” L (76 cm x 110 cm) Maximum Performance: 1,700 27.8″ x 39.4″ SPH Warm Up Time: 8 minutes PET Film Processing Module: Optional Jogger 760*: Optional Film Loader (Electric): Optional Foliant Foiler: Optional *Important: The machine must be operated with a jogger.

Issue rendering sage

The Foliant Taurus 760 NG is a fast and Compact Industrial Laminating Machine, constructed for nonstop work with an integrated suction feeder and high-speed bump separator, and with options like a pallet stacker and Foliant Foiler.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a suction feed head

• Single-sided thermal industrial laminator

• Film is mounted on an air shaft that allows convenient, easy and precise film positioning

-

Foliant Vega 400A Laminator

GM-MSC-FOLVEG400AVega 400A

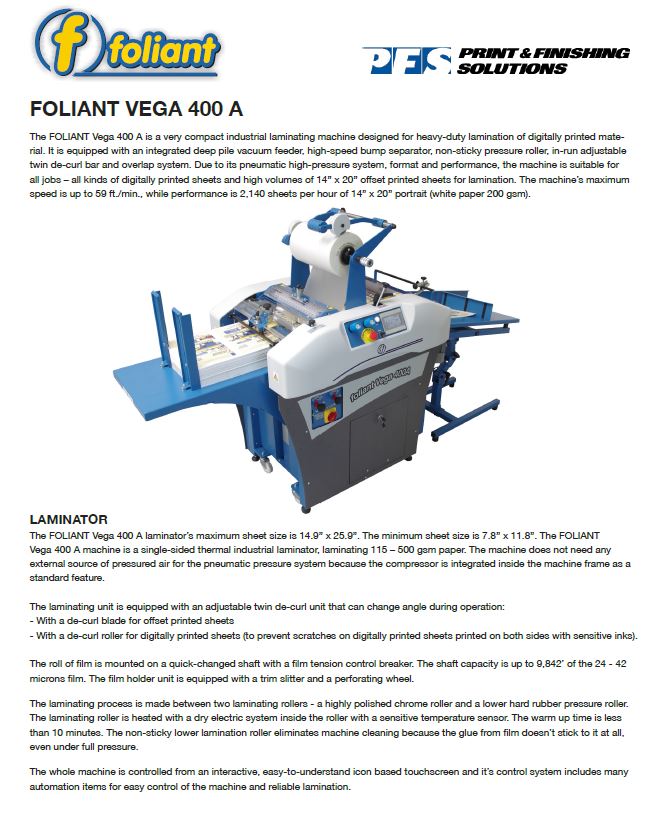

The Foliant Vega 400A Industrial Laminating Machine is a very compact industrial laminating machines, designed for heavy-duty digitally printed material. It is equipped with an integrated deep pile vacuum feeder, high-speed bump separator, non-sticky pressure roller and in-run adjustable twin de-curl bar and overlap system. Due to its pneumatic high-pressure system, format and performance the machine is suitable for all jobs – all kinds of digital printed sheets and high volumes of offset printed sheets 13.9″ x 19.7″ for lamination. The machine’s maximum speed is up to 59 feet/minute, while performance is over 2,100 sheets per hour of 14″ x 20″ portrait (white paper 200 gsm).

- Easy operation

- Equipped with a rising pile front separation stream feeder with a vacuum belt head

- Single-sided thermal industrial laminator

- Film is mounted on a quick change shaft with a film tension control breaker

- Film holder unit is equipped with a trim slitter and perforation wheel

- Does not need external source for pressured air

- Pressure is pneumatically adjustable

- De-curl blade for offset printed sheets

- De-curl roller for digitally printed sheets

- Icon based touchscreen control system for easy automation

- Integrated bump sheet separator

- Optional Reception Unit 400*, Jogger 400*, Foliant Foiler, pneumatic separation, air shaft and extra film supply roll shaft available

*Important – The machine must be operated with either a Reception Unit or a Jogger.

Maximum Speed: 59 feet/minute Feeding: Automatic Feeding System: Vacuum Belt Feeder Load Capacity: 11 ” (28 cm) Overlap Control: In-run Adjustable Overlap Accuracy: ± 0.08″ Separation: Automatic Paper Weight: 115 – 350 gsm Main Rollers Pressure: Pneumatic Minimum Sheet Size: 7.8″ W x 11.8” L (20 cm x 30 cm) Maximum Sheet Size: 14.9” W x 25.9″ L (38 cm x 66 cm) Maximum Performance: 2,100 14″ x 20″ SPH Warm Up Time: 8 minutes Reception Unit: Standard Jogger: Optional Non-sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The FOLIANT Vega 400 A is a very compact industrial laminating machine designed for heavy-duty lamination of digitally printed material. It is equipped with an integrated deep pile vacuum feeder, high-speed bump separator, non-sticky pressure roller, in-run adjustable twin de-curl bar and overlap system.

• Maximum speed: 59 feet/min.

• Load capacity: 11"

• Max. sheet size: 14.9" x 25.9"

• Warm up time: 8 mins.

-

Foliant Vega 400SF Laminator

GM-MSC-FOLVEG400SFThe FOLIANT Vega 400 SF is a very compact industrial laminating machine designed for heavy-duty lamination of digital and offset outputs (max. format 15” x 26”). It is equipped with an integrated deep pile suction feeder (original from offset printing machines), pneumatic high-speed bump separator, adjustable dual de-curl bar and overlap system. Due to its high pneumatic pressure system, format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets 14” x 20” for lamination. The machine’s maximum speed is up to 65 ft./min., while performance is 2,300 sheets per hour of 14” x 20” portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Vega 400 SF laminator’s maximum sheet size is 15” x 26”. The minimum sheet size is 7.8” x 11.8”. The FOLIANT Vega 400 SF machine is a single-sided thermal industrial laminator, laminating 115 – 500 gsm paper. The machine needs an external source of pressured air for the pneumatic pressure system 87.0 psi - 116.0 psi / 5.3 cfm.

The laminating unit is equipped with an adjustable dual de-curl bar that can change angle during operation:

- With a de-curl blade for offset printed sheets

- With a de-curl roller for digitally printed sheets (to prevent scratches on digitally printed sheets printed on both sides with sensitive inks).

The whole machine is controlled with an interactive, easy-to-understand icon based touchscreen and its control system includes several automation items for easy control of the machine and reliable lamination.

Comparing competitive products, the Vega 400 SF machine’s control system allows more automation:

- Intelligent job interruption, without having to re-install or re-adjust the machine, saves plenty of time.

- The first sheet of a new job automatically, safely and easily passes through the master roller’s gap to be the best position.

- Automatic regeneration of master pressure.

The roll of film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 9,842’ of the 24 - 42 microns film. The standard film roll core is 3”. The film holder unit is equipped with an in-line trim slitter and perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller and a lower hard rubber pressure roller. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller with a sensitive temperature sensor. The warm up time is less than 10 minutes.

Maximum Speed: 65 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 11” Overlaps: In-run adjustable Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Integrated Compressor: Included Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 7.8” W x 11.8” L Maximum Sheet Size: 20” W x 30” L Maximum Performance: 2,300 14″ x 20″ Portrait SPH Warm Up Time: 8 minutes Floor Space with Jogger: 71.6"W x 78"L Weight: 838 lbs. Temperature Control: 176° – 284° F Dual De-curl Bar: Standard Reception Unit RU400: Optional Jogger 400: Optional Non-sticky Pressure Roller: Optional Air Shaft: Optional Pneumatic Separation: Optional Foliant Foiler: Optional Issue rendering sage

Due to its high pneumatic pressure system, format and performance, the Foliant Vega 400SF is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 14″ x 20″ for lamination. It is equipped with integrated deep pile suction feeder, pneumatic high-speed bump separator, adjustable dual de-curl bar and overlap system.

• Easy operation

• Rising pile suction feeder

• Single-sided thermal industrial laminator -

Foliant Vega 530A Laminator

GM-MSC-FOLVEG530AThe FOLIANT Vega 530 A is a very compact industrial laminating machine designed for heavy-duty lamination of digital and offset ouotputs (max. format 20.8" x 29.5"). It is equipped with an integrated deep pile vacuum feeder, high-speed bump separator, and adjustable twin de-curl bar and overlap system. Due to its pneumatic high-pressure system (with an integrated compressor inside the machine frame), format and performance, the machine is suitable for all jobs - all kinds of digitally printed sheets and high volumes of 19.7" x 27.8" offset printed sheets for lamination. The machine's maximum speed is up to 59 ft/min, while performance is 1,550 sheets per hour of 19.7" x 27.8" portrait or 3,000 sheets 14" x 20" landscape (white paper 200 gsm).

LAMINATOR

The FOLIANT Vega 530 A laminator’s maximum sheet size is 20.8” x 29.5”. The minimum sheet size is 7.8” x 11.8”. The FOLIANT

Vega 530 A machine is a single-sided thermal industrial laminator, laminating 115 – 500 gsm paper. The machine does not need any external source of pressured air for the pneumatic pressure system because the compressor is integrated inside the machine frame as a standard feature.The laminating unit is equipped with an adjustable twin de-curl unit that can change angle during the operation:

- With a de-curl blade for offset printed sheets

- With a de-curl roller for digitally printed sheets (to prevent scratches on digitally printed sheets printed on both sides with sensitive inks).The roll of film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 9,842’ of the 24 - 42 microns film. The film holder unit is equipped with a trim slitter and perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller and a lower hard rubber pressure roller. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller with a sensitive temperature sensor. The warm up time is less than 10 minutes. The non-sticky lower lamination roller eliminates machine cleaning because the glue from film doesn’t stick to it at all, even under full pressure.

The whole machine is controlled from an interactive, easy-to-understand icon based touchscreen and it’s control system includes many automation items for easy control of the machine and reliable lamination.

Maximum Speed: 59 feet/minute Feeding: Automatic Feeding System: Vacuum Belt Feeder Load Capacity: 11” Overlap Control: In-run Adjustable Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 350 gsm Integrated Compressor: Included Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 7.8” W x 11.8” L Maximum Sheet Size: 20.8” W x 29.5” L Maximum Performance: 1,550 19.7″ x 27.8″ SPH Portrait

3,000 14" x 20" SPH Landscape

Warm Up Time: 8 minutes Twin De-curl Bar, Adjustable: Standard Reception Unit RU530: Optional Jogger 530: Optional Integrated Motorized Stacker: Optional Non-sticky Pressure Roller: Optional Air Shaft: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Vega 530A Laminating Machine is a very compact industrial laminating machine, designed for heavy-duty in-house lamination of digital and offset printing. It is equipped with an integrated deep pile vacuum feeder, high-speed bump separator, adjustable twin de-curl bar and overlap system.

• Easy operation

• Equipped with a rising pile front separation stream feeder with a vacuum belt head

• Single-sided thermal industrial laminator -

Foliant Taurus 760 NG 4X4 Laminator

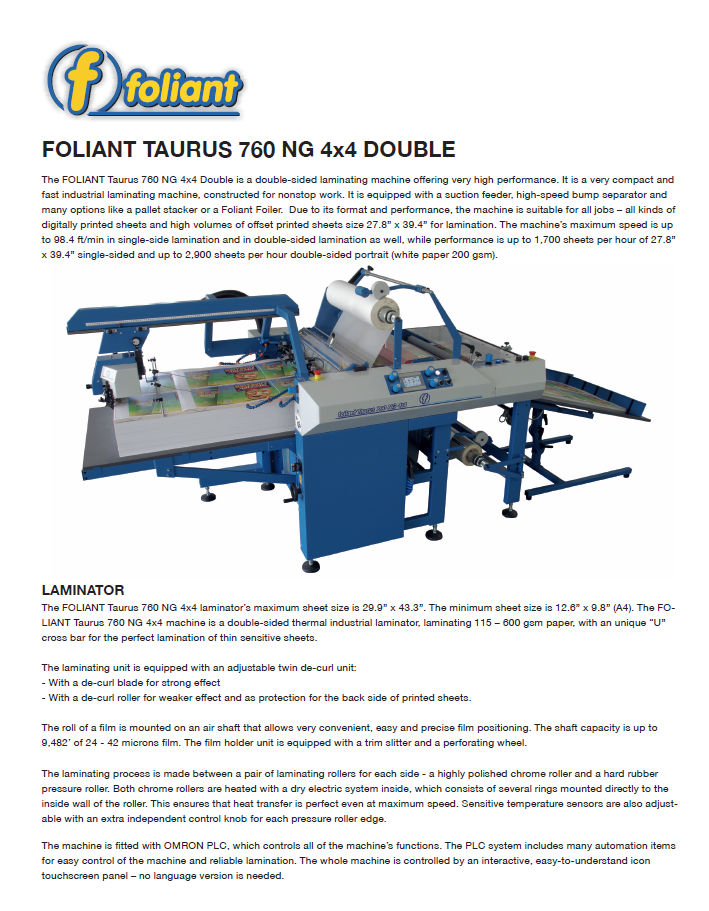

GM-MSC-FOL760NG4X4The FOLIANT Taurus 760 NG 4x4 Double is a double-sided laminating machine offering very high performance. It is a very compact and fast industrial laminating machine, constructed for nonstop work. It is equipped with a suction feeder, high-speed bump separator and many options like a pallet stacker or a Foliant Foiler. Due to its format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 27.8” x 39.4” for lamination. The machine’s maximum speed is up to 98.4 ft/min in single-side lamination and in double-sided lamination as well, while performance is up to 1,700 sheets per hour of 27.8” x 39.4” single-sided and up to 2,900 sheets per hour double-sided portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Taurus 760 NG 4x4 laminator’s maximum sheet size is 29.9” x 43.3”. The minimum sheet size is 12.6” x 9.8” (A4). The FOLIANT Taurus 760 NG 4x4 machine is a double-sided thermal industrial laminator, laminating 115 – 600 gsm paper, with an unique “U” cross bar for the perfect lamination of thin sensitive sheets.The laminating unit is equipped with an adjustable twin de-curl unit:

- With a de-curl blade for strong effect

- With a de-curl roller for weaker effect and as protection for the back side of printed sheets.The roll of a film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 9,482’ of 24 - 42 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is made between a pair of laminating rollers for each side - a highly polished chrome roller and a hard rubber pressure roller. Both chrome rollers are heated with a dry electric system inside, which consists of several rings mounted directly to the inside wall of the roller. This ensures that heat transfer is perfect even at maximum speed. Sensitive temperature sensors are also adjustable with an extra independent control knob for each pressure roller edge.

The machine is fitted with OMRON PLC, which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive, easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed (single/double): 98.4 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 15.7” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L Maximum Sheet Size: 29.9” W x 43.3” L Maximum Performance: 1,700/2,900 27.8″ x 39.4″ SPH Warm Up Time: 8 minutes Jogger 760: Optional Film Loader (Electric): Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Taurus 760 NG 4×4 is a Double-sided Laminating Machine offering very high performance. It comes equipped with an suction feeder, high-speed bump separator and many options like a pallet stacker or a Foliant Foiler.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a suction feed head

• Single-sided and double-sided thermal industrial laminator -

Foliant Taurus 530 NG Laminator

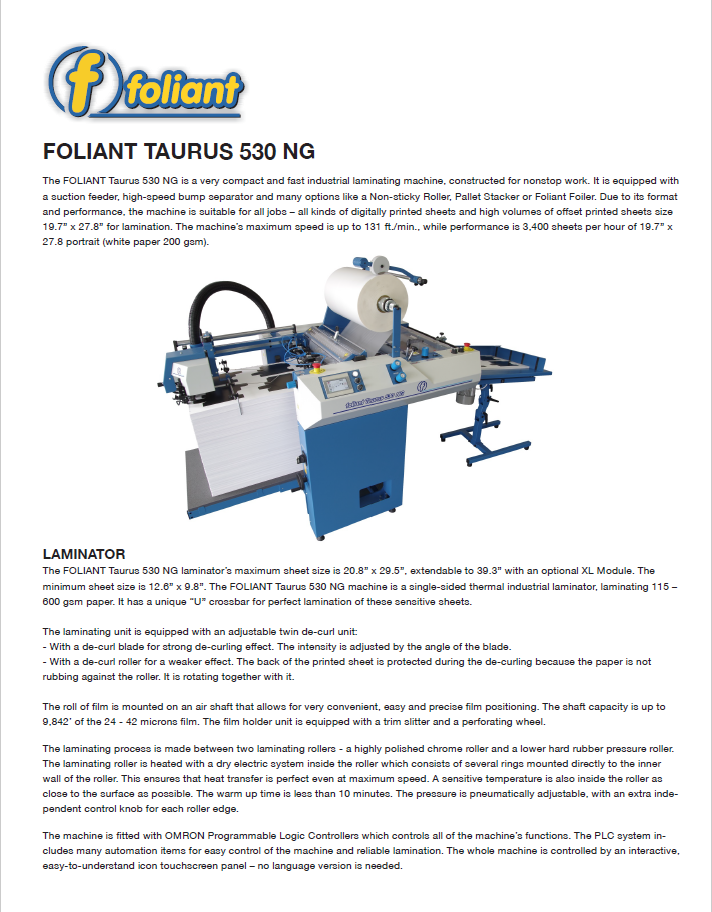

GM-MSC-FOLTAU530NGThe FOLIANT Taurus 530 NG is a very compact and fast industrial laminating machine, constructed for nonstop work. It is equipped with a suction feeder, high-speed bump separator and many options like a Non-sticky Roller, Pallet Stacker or Foliant Foiler. Due to its format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 19.7” x 27.8” for lamination. The machine’s maximum speed is up to 131 ft./min., while performance is 3,400 sheets per hour of 19.7” x 27.8 portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Taurus 530 NG laminator’s maximum sheet size is 20.8” x 29.5”, extendable to 39.3” with an optional XL Module. The minimum sheet size is 12.6” x 9.8”. The FOLIANT Taurus 530 NG machine is a single-sided thermal industrial laminator, laminating 115 – 600 gsm paper. It has a unique “U” crossbar for perfect lamination of these sensitive sheets.The laminating unit is equipped with an adjustable twin de-curl unit:

- With a de-curl blade for strong de-curling effect. The intensity is adjusted by the angle of the blade.

- With a de-curl roller for a weaker effect. The back of the printed sheet is protected during the de-curling because the paper is not

rubbing against the roller. It is rotating together with it.The roll of film is mounted on an air shaft that allows for very convenient, easy and precise film positioning. The shaft capacity is up to 9,842’ of the 24 - 42 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller which consists of several rings mounted directly to the inner wall of the roller. This ensures that heat transfer is perfect even at maximum speed. A sensitive temperature is also inside the roller as close to the surface as possible. The warm up time is less than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge.The machine is fitted with OMRON Programmable Logic Controllers which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive, easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed: 131 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 21.2” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L Maximum Sheet Size: 20.8” W x 29.5” L Maximum Performance: 3,400 19.7″ x 27.8″ SPH Warm Up Time: 8 minutes PET Module: Optional Jogger 530: Optional Integrated Motorized Stacker: Optional Film Loader (Electric): Optional Non-sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Taurus 530 NG is a very fast Compact Industrial Laminating Machine, constructed for nonstop work. It is equipped with a suction feeder, a high-speed bump separator and many options like non-sticky roller, pallet stacker or Foliant Foiler. Due to its format and the performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets 19.7″ x 27.8″ for lamination.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a suction feed head

• Single-sided thermal industrial laminator

-

Foliant Taurus 530 NG 4X4 Laminator

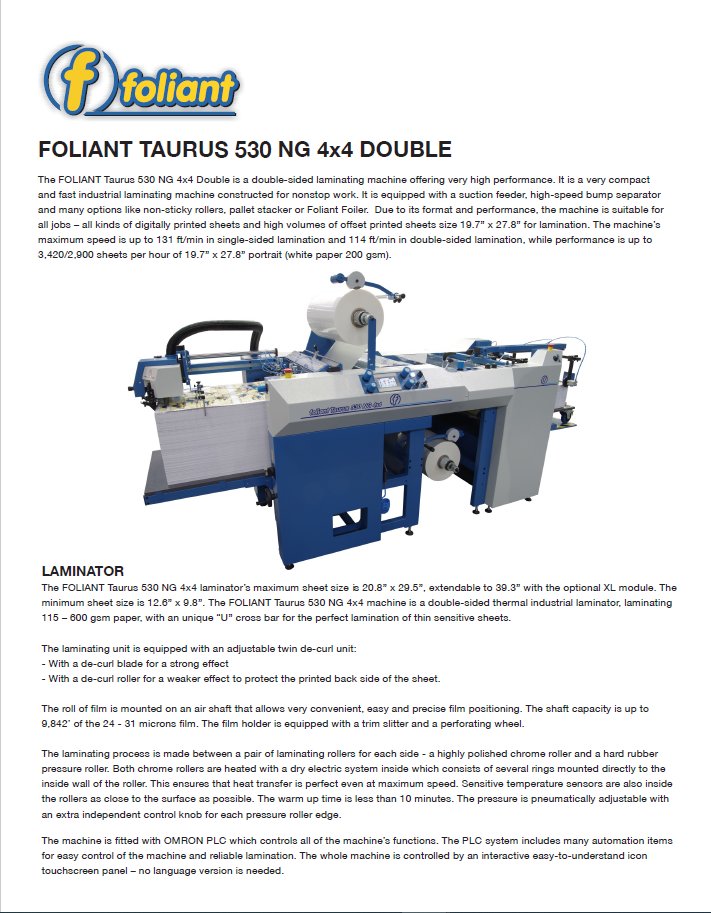

GM-MSC-FOLTAU530NG4X4The FOLIANT Taurus 530 NG 4x4 Double is a double-sided laminating machine offering very high performance. It is a very compact and fast industrial laminating machine constructed for nonstop work. It is equipped with a suction feeder, high-speed bump separator and many options like non-sticky rollers, pallet stacker or Foliant Foiler. Due to its format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 19.7” x 27.8” for lamination. The machine’s maximum speed is up to 131 ft/min in single-sided lamination and 114 ft/min in double-sided lamination, while performance is up to 3,420/2,900 sheets per hour of 19.7” x 27.8” portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Taurus 530 NG 4x4 laminator’s maximum sheet size is 20.8” x 29.5”, extendable to 39.3” with the optional XL module. The minimum sheet size is 12.6” x 9.8”. The FOLIANT Taurus 530 NG 4x4 machine is a double-sided thermal industrial laminator, laminating 115 – 600 gsm paper, with an unique “U” cross bar for the perfect lamination of thin sensitive sheets.

The laminating unit is equipped with an adjustable twin de-curl unit:

- With a de-curl blade for a strong effect

- With a de-curl roller for a weaker effect to protect the printed back side of the sheet.The roll of film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 9,842’ of the 24 - 31 microns film. The film holder is equipped with a trim slitter and a perforating wheel.

The laminating process is made between a pair of laminating rollers for each side - a highly polished chrome roller and a hard rubber pressure roller. Both chrome rollers are heated with a dry electric system inside which consists of several rings mounted directly to the inside wall of the roller. This ensures that heat transfer is perfect even at maximum speed. Sensitive temperature sensors are also inside the rollers as close to the surface as possible. The warm up time is less than 10 minutes. The pressure is pneumatically adjustable with an extra independent control knob for each pressure roller edge.

The machine is fitted with OMRON PLC which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed (single/double): 130/114 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 21.2” Overlaps: In-run adjustable Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Integrated Compressor: Included Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L Maximum Sheet Size: 20.8” W x 29.5” L Maximum Performance: 2,300 14″ x 20″ Portrait SPH Warm Up Time: 8 minutes Floor Space with Jogger: 71.6"W x 78"L Temperature Control: 176° – 284° F Jogger 530: Optional XL Module (sheets up to 39.3"): Optional Integrated Pallet Stacker: Optional Film Loader (Electric): Optional Non-Sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The FOLIANT Taurus 530 NG 4×4 Double is a double-sided laminating machine offering very high performance. It is a very compact and fast industrial laminating machine, constructed for nonstop work. It is equipped with a suction feeder, high speed bump separator and many options like non-sticky rollers, pallet stacker or Foliant Foiler. Due to its format and performance the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 19.7″ x 27.8″ for lamination.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a suction feed head

• Single-sided thermal industrial laminator -

Foliant Mercury 400 NG 4x4 Laminator

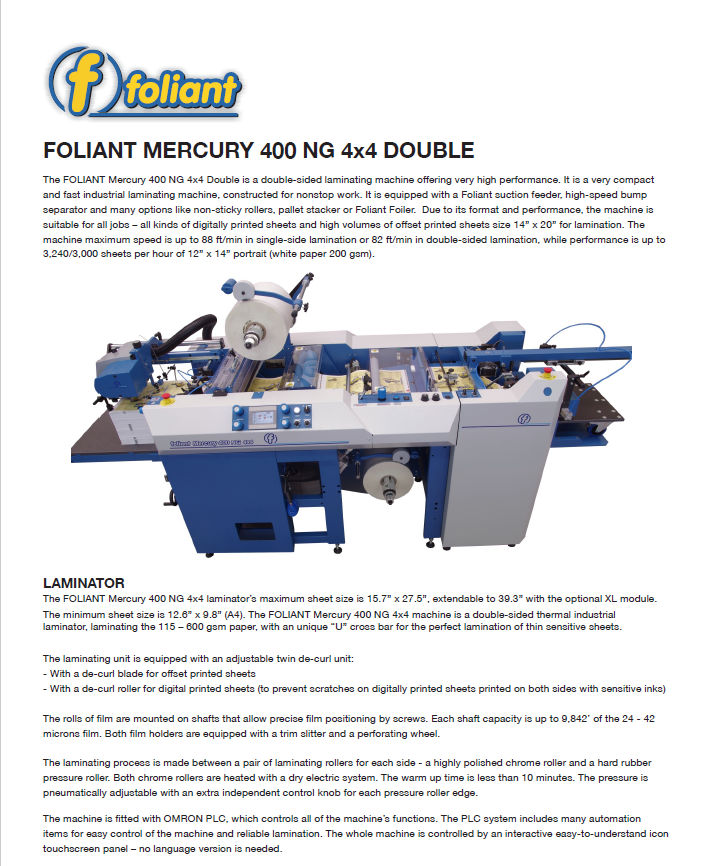

GM-MSC-FOL400NG4X4The FOLIANT Mercury 400 NG 4x4 Double is a double-sided laminating machine offering very high performance. It is a very compact and fast industrial laminating machine, constructed for nonstop work. It is equipped with a Foliant suction feeder, high-speed bump separator and many options like non-sticky rollers, pallet stacker or Foliant Foiler. Due to its format and performance, the machine is suitable for all jobs - all kinds of digitally printed sheets and high volumes of offset printed sheet sizes 14" x 20" for lamination. The machine maximum speed is up to 88 ft/min in single-side lamination or 82 ft/min double-sided lamination, while performance is up to 3,240/3,000 sheets per hour of 12" x 14" portrait (white paper 200 gsm)

LAMINATOR

The FOLIANT Mercury 400 NG 4x4 laminator’s maximum sheet size is 15.7” x 27.5”, extendable to 39.3” with the optional XL module. The minimum sheet size is 12.6” x 9.8” (A4). The FOLIANT Mercury 400 NG 4x4 machine is a double-sided thermal industrial laminator, laminating the 115 – 600 gsm paper, with an unique “U” cross bar for the perfect lamination of thin sensitive sheets.The laminating unit is equipped with an adjustable twin de-curl unit:

-With a de-curl blade for offset printed sheets

-With a de-curl roller for digital printed sheets (to prevent scratches on digitally printed sheets printed on both sides with sensitive inks)The rolls of film are mounted on shafts that allow precise film positioning by screws. Each shaft capacity is up to 9,842’ of the 24 - 42 microns film. Both film holders are equipped with a trim slitter and a perforating wheel.

The laminating process is made between a pair of laminating rollers for each side - a highly polished chrome roller and a hard rubber pressure roller. Both chrome rollers are heated with a dry electric system. The warm up time is less than 10 minutes. The pressure is pneumatically adjustable with an extra independent control knob for each pressure roller edge.

The machine is fitted with OMRON PLC, which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed (single/double): 88/82 feet/minute Feeding: Automatic Feeding System: Foliant Suction Feed Head Feeder Load Capacity: 21.2” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L Maximum Sheet Size: 15.7” W x 27.5” L Maximum Performance: 3,240/3,000 14″ x 20″ SPH Warm Up Time: 8 minutes Modular for PET Films Processing: Standard Floor Space w/Jogger: 41.3"W x 122"L Jogger 400: Optional XL Module (sheets up to 39.3"): Optional Pallet Stacker (Motorized): Optional Pallet Stacker Capacity: 27.5" Film Loader (Electric): Optional Film Micro Adjustment Air Shaft: Optional, up to 2x Non-Sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Mercury 400NG 4×4 is a Double-sided Industrial Laminating Machine constructed for nonstop heavy-duty digital and offset output lamination. Due to its high-pressure system, format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets, size 13.9″ x 19.7″ for lamination.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a Heidelberg suction feed head

• Single-sided and double-sided thermal industrial laminator -

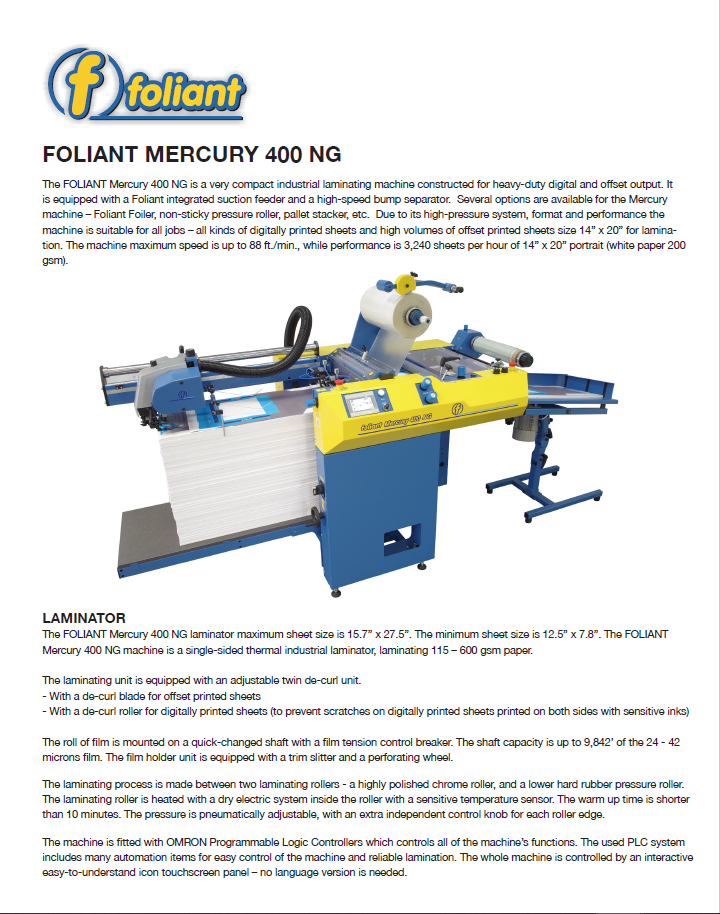

Foliant Mercury 400 NG Laminator

GM-MSC-FOL400NGThe FOLIANT Mercury 400 NG is a very compact industrial laminating machine constructed for heavy-duty digital and offset output. It is equipped with a Foliant integrated suction feeder and a high-speed bump separator. Several options are available for the Mercury machine – Foliant Foiler, non-sticky pressure roller, pallet stacker, etc. Due to its high-pressure system, format and performance the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 14” x 20” for lamination. The machine maximum speed is up to 88 ft./min., while performance is 3,240 sheets per hour of 14” x 20” portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Mercury 400 NG laminator maximum sheet size is 15.7” x 27.5”. The minimum sheet size is 12.5” x 7.8”. The FOLIANT

Mercury 400 NG machine is a single-sided thermal industrial laminator, laminating 115 – 600 gsm paper.The laminating unit is equipped with an adjustable twin de-curl unit.

- With a de-curl blade for offset printed sheets

- With a de-curl roller for digitally printed sheets (to prevent scratches on digitally printed sheets printed on both sides with sensitive inks)The roll of film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 9,842’ of the 24 - 42 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller with a sensitive temperature sensor. The warm up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge.

The machine is fitted with OMRON Programmable Logic Controllers which controls all of the machine’s functions. The used PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed: 88 feet/minute Feeding: Automatic Feeding System: Foliant Suction Feed Head Feeder Load Capacity: 21.2” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.5” W x 9.8” L Maximum Sheet Size: 15.7” W x 27.5” L Maximum Performance: 3,240 (14″ x 20″) SPH Warm Up Time: 8 minutes Modular for PET Films Processing: Optional Floor Space w/Jogger: 41"W x 90.5"L Jogger 400: Optional XL Module for Sheets 15.7" x 39.4": Optional Pallet Stacker: Optional Pallet Stacker Capacity: Optional Film Loader (Electric): Optional Film Micro Adjustment Air Shaft: Optional, up to 2x Film Loader/Manipulator: Optional Non-sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Mercury 400 NG is a Compact Industrial Laminating Machine constructed for heavy-duty digital and offset output. It is equipped with a Foliant integrated suction feeder and a high-speed bump separator. Due to its high-pressure system, format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets, size 14″ x 20″ for lamination.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a Foliant suction feed head

• Single-sided thermal industrial laminator -

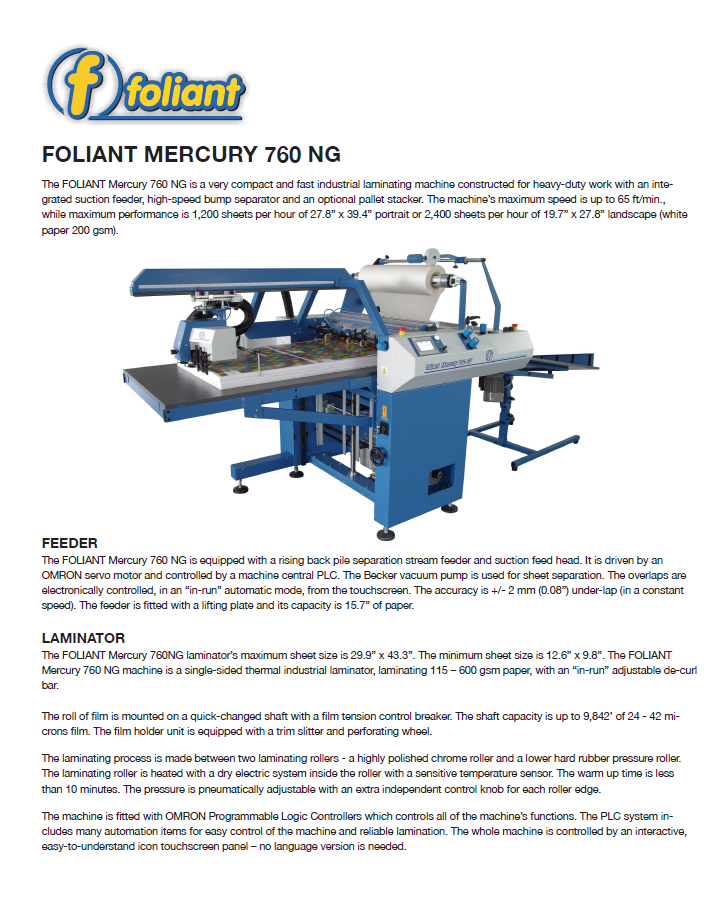

Foliant Mercury 760 NG DS Laminator

GM-MSC-FOLMER760NGThe FOLIANT Mercury 760 NG is a very compact and fast industrial laminating machine constructed for heavy-duty work with an integrated suction feeder, high-speed bump separator and an optional pallet stacker. The machine’s maximum speed is up to 65 ft/min., while maximum performance is 1,200 sheets per hour of 27.8” x 39.4” portrait or 2,400 sheets per hour of 19.7” x 27.8” landscape (white paper 200 gsm).

FEEDER

The FOLIANT Mercury 760 NG is equipped with a rising back pile separation stream feeder and suction feed head. It is driven by an OMRON servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheet separation. The overlaps are electronically controlled, in an “in-run” automatic mode, from the touchscreen. The accuracy is +/- 2 mm (0.08”) under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is 15.7” of paper.LAMINATOR

The FOLIANT Mercury 760NG laminator’s maximum sheet size is 29.9” x 43.3”. The minimum sheet size is 12.6” x 9.8”. The FOLIANT

Mercury 760 NG machine is a single-sided thermal industrial laminator, laminating 115 – 600 gsm paper, with an “in-run” adjustable de-curl bar.The roll of film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 9,842’ of 24 - 42 microns film. The film holder unit is equipped with a trim slitter and perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller a sensitive temperature sensor. The warm up time is less than 10 minutes. The pressure is pneumatically adjustable with an extra independent control knob for each roller edge.

The machine is fitted with OMRON Programmable Logic Controllers which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The whole machine is controlled by an interactive, easy-to-understand icon touchscreen panel – no language version is needed.

Maximum Speed: 65 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 15.7” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Integrated Compressor: Included Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.6” W x 9.8” L Maximum Sheet Size: 29.9” W x 43.3” L Maximum Performance: 1,200 27.8″ x 39.4″ SPH Warm Up Time: 8 minutes Modular for PET Films Processing: Optional Jogger 760: Optional Film Loader (Electric): Optional Film Micro Adjustment Shaft: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Mercury 760 NG is a heavy-duty Compact Industrial Fast Laminating Machine, constructed for heavy-duty work with an integrated suction feeder, a high-speed bump separator and an optional pallet stacker. The machine’s maximum speed is up to 65 feet/minute.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a suction feed head

• Single-sided thermal industrial laminator -

Foliant Taurus 400 NG Laminator

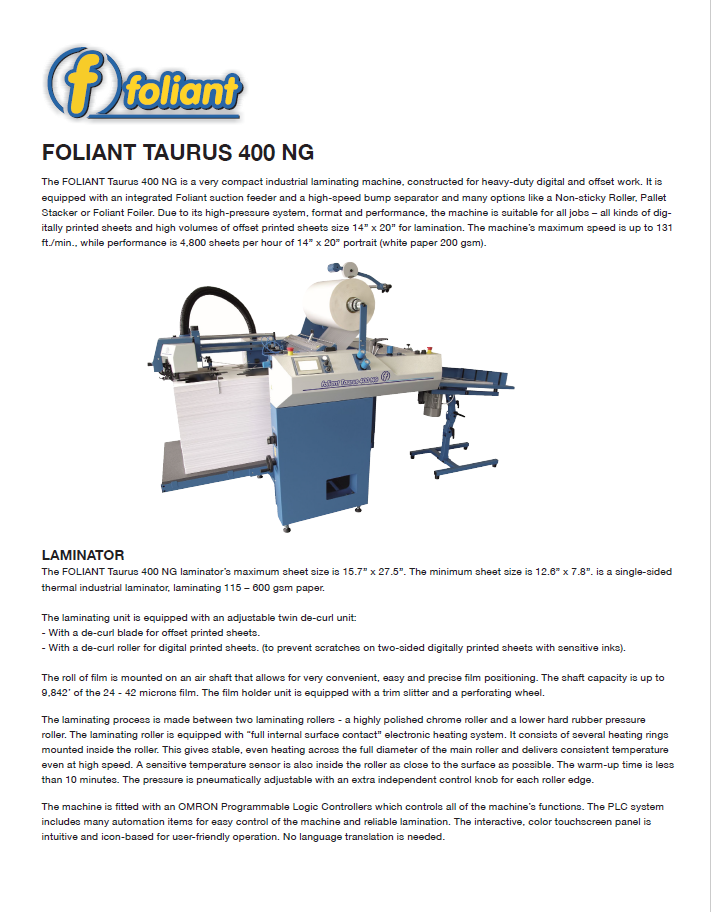

GM-MSC-FOLTAU400NGThe FOLIANT Taurus 400 NG is a very compact industrial laminating machine, constructed for heavy-duty digital and offset work. It is equipped with an integrated Foliant suction feeder and a high-speed bump separator and many options like a Non-sticky Roller, Pallet Stacker or Foliant Foiler. Due to its high-pressure system, format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets size 14” x 20” for lamination. The machine’s maximum speed is up to 131 ft./min., while performance is 4,800 sheets per hour of 14” x 20” portrait (white paper 200 gsm).

LAMINATOR

The FOLIANT Taurus 400 NG laminator’s maximum sheet size is 15.7” x 27.5”. The minimum sheet size is 12.6” x 7.8”. is a single-sided thermal industrial laminator, laminating 115 – 600 gsm paper.The laminating unit is equipped with an adjustable twin de-curl unit:

- With a de-curl blade for offset printed sheets.

- With a de-curl roller for digital printed sheets. (to prevent scratches on two-sided digitally printed sheets with sensitive inks).The roll of film is mounted on an air shaft that allows for very convenient, easy and precise film positioning. The shaft capacity is up to 9,842’ of the 24 - 42 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is made between two laminating rollers - a highly polished chrome roller and a lower hard rubber pressure roller. The laminating roller is equipped with “full internal surface contact” electronic heating system. It consists of several heating rings mounted inside the roller. This gives stable, even heating across the full diameter of the main roller and delivers consistent temperature even at high speed. A sensitive temperature sensor is also inside the roller as close to the surface as possible. The warm-up time is less than 10 minutes. The pressure is pneumatically adjustable with an extra independent control knob for each roller edge.

The machine is fitted with an OMRON Programmable Logic Controllers which controls all of the machine’s functions. The PLC system includes many automation items for easy control of the machine and reliable lamination. The interactive, color touchscreen panel is intuitive and icon-based for user-friendly operation. No language translation is needed.

Maximum Speed: 88 feet/minute Feeding: Automatic Feeding System: Suction Feed Head Feeder Load Capacity: 21.2” Overlaps: Automatic, PLC Control Overlap Accuracy: ± 0.08″ Separation: Automatic, Bump Rollers Paper Weight: 115 – 600 gsm Main Rollers Pressure: Pneumatic External Compressor: 150 l / minute, 6 – 8 bar Minimum Sheet Size: 12.5” W x 9.8” L Maximum Sheet Size: 15.7” W x 27.5” L Maximum Performance: 3,240 (14″ x 20″) SPH Warm Up Time: 8 minutes Modular for PET Films Processing: Optional Floor Space w/Jogger: 41"W x 90.5"L Jogger 400: Optional XL Module for Sheets 15.7" x 39.4": Optional Pallet Stacker: Optional Pallet Stacker Capacity: 27.5" Integrated Motorized Stacker: Optional Film Loader (Electric): Optional Film Micro Adjustment Air Shaft: Optional, up to 2x Film Loader/Manipulator: Optional Non-sticky Pressure Roller: Optional Foliant Foiler: Optional Issue rendering sage

The Foliant Taurus 400 NG is a very Compact Industrial Laminating Machine, constructed for a heavy-duty digital and offset work. Due to its high-pressure system, the format and the performance of the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets, size 14″ x 20″ for lamination.

• Easy operation

• Equipped with a rising back pile separation stream feeder with a Foliant suction feed head

• Single-sided thermal industrial laminator